Africa Carbon Markets Initiative builds on momentum from COP27, announces 13 action programmes

Chilling Prospects 2022: Protecting medicines and vaccines through data analytics across the cold chain

Gathering real-time and continuous temperature data

What we have learned in recent years is that when countries can see into their cold chain, decision-makers at all levels of the health system have a shared, objective understanding of cold chain performance. They can make informed decisions around planning, procurement and maintenance, and most importantly, they are better equipped to keep vaccines safe and potent. RTM devices automatically gather real-time, objective and continuous temperature data from vaccine storage and transport equipment, share those data with multiple stakeholders, and automate alerts and dashboard analytics that synthesize and contextualize the data.

The system saves health workers time by automatically and remotely collecting data, and it eliminates opportunities for human-prone errors from paper-based systems. It also provides a cost-effective and customizable way for countries to own their data, identify problems, procure and maintain equipment, and maximize their capacity for safely refrigerating their vaccine supplies.

ColdTrace currently protects vaccines for one in ten babies born around the world every year. The system has been shown to reduce damage to vaccines by heat and cold by 68 percent and 67 percent, respectively. Helping countries avoid vaccine degradation due to temperature exposure — high or low — reduces waste and ensures effective immunization, ultimately reducing outbreaks of disease.

Kenya and Tanzania are currently partnering with Nexleaf to get the right data to the right people at the right time, providing Ministry of Health personnel with the information they need to keep their fleet of vaccine fridges and transport carriers up and running. In December 2021, staff at a district vaccine store (DVS) in Tanzania received SMS alerts concerning a couple of faulty fridges and after looking at the data analytics, it was clear there had been a power outage. These data prompted a fast response from the DVS staff and power company who were able to resolve the issue within a few days, restoring reliable cooling to a store that plays a critical role in assuring the safety of thousands of vaccines distributed to local facilities.

Tracking COVID-19 vaccines in Kenya

This real-time visibility into cold chain performance took on an even greater significance in early 2021 when countries started receiving thousands of doses of COVID-19 vaccines; Nexleaf’s work in remote temperature monitoring during transportation was well underway when the Kenya Ministry of Health requested sensor devices to monitor its valuable Pfizer and Moderna COVID-19 vaccines to ensure they stayed safe. So far, Nexleaf’s battery-powered and Bluetooth-enabled Trek device has been used to monitor all the transport routes of Pfizer (795,600 doses) and Moderna (880,000+ doses) vaccines that have been transported from the central vaccine store to the nine regional vaccine stores throughout Kenya.

The data collected via Trek are shared with health workers to show how the vaccines fared throughout the journey, providing evidence that vaccines are still potent and will protect the population effectively. The data are also organized into various visualizations that Ministry personnel can use to evaluate which vaccine distribution events maintained safe temperatures most effectively. These analytics have allowed for evidence-based discussions around the vaccine cold chain, not only for COVID-19 vaccines, but all childhood vaccines. With very clear protocols around vaccine temperature requirements and vaccine viability, health workers can use Trek data to make informed decisions rather than relying on guesswork, dispose of spoiled vaccines, and take steps to protect vaccines before they lose potency.

Key to the value of remote temperature monitoring is the remote and automated nature of the data the system gathers. Using sensors to log and upload temperature and power availability data, the system eliminates error-prone manual data entry and enables push-button time-series data visualization. It can also provide insight into health facility power capacity, revealing how many hours of grid power flow to the facility, or whether a solar-battery system is functioning properly. Trek provides GPS route data that can give planners visibility into the locations and timing of problems that hinder efficient vaccine delivery.

As we look to the future, we believe the key to total system improvement lies in full end-to-end RTM at every storage point and transport leg of the vaccine cold chain. By 2025, we hope to see end-to-end RTM implemented in three low- and middle-income countries (LMICs), generating critical data to safeguard vaccines.

Our most crucial measure of success, however, is seeing evidence that the central Ministry of Health, health workers and personnel at every level are using data gathered by the system to guide their actions in their day-to-day work as well as in their country-wide cold chain planning, procurement and management. We also believe that the system will achieve its maximum utility when power availability and Trek route data can be leveraged effectively to provide benefits to planners beyond vaccine management, as more lifesaving equipment (such as oxygen concentrators) and critical medicines (such as insulin) are deployed to more and more remote clinics.

Meet our Global Panel on Access to Cooling member from Nexleaf Analytics

Goal 7 target

SDG 7.3 - Energy efficiencyChilling Prospects 2022: Expanding the vaccine cold chain in Kenya through innovative cooling solutions

The effort to update Kenya’s cold chain inventory began in 2016 with the country’s successful application to Gavi’s CCEOP and a World Bank loan that resulted in the deployment of 3,082 new refrigerators. 20 percent of these appliances were solar-direct drive (SDD) refrigerators, which use solar energy via photovoltaic panels to maintain the required 2–8°C for vaccine storage. SDD refrigerators allow for expansion to health facilities with no electricity, are low maintenance and have low OPEX costs as they do not require a battery, electricity, or backup power source. The remaining 80 percent of appliances procured were ice-lined refrigerators. While they are mains-powered, the water or PCM-based coolant packs lining the walls enable long holdover times – a minimum of 20 hours and often more than two days.

As shown in Figure 1, 2,463 units of optimal CCE were introduced to Kenya through these investments over a five-year period, increasing the rate of optimized equipment to 33 percent by 2021. This was accomplished through a blend of deployment across sub-optimal sites, new sites, those with unqualified storage refrigerators [9], and facilities that previously had no CCE. The number of sub-optimal sites decreased by 18 percent (4,036 sites to 3,300), however, this figure also accounts for the introduction of new sub-optimal equipment at other site types. [10]

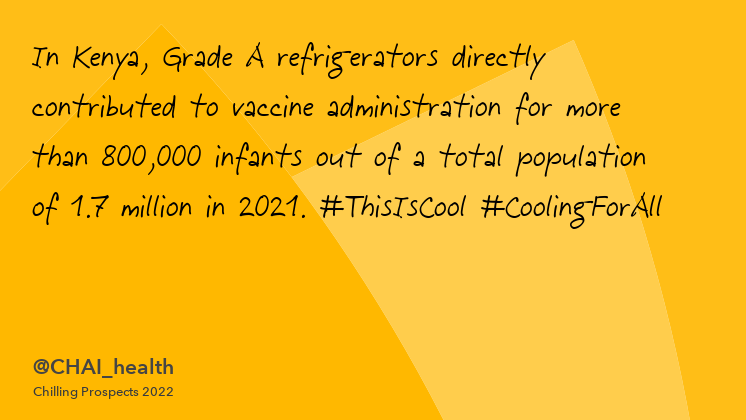

In 2021, these Grade A refrigerators directly contributed to vaccine administration for 833,238 infants out of a total population of 1.7 million (50 percent) despite only comprising a third of the total CCE. [11]

The road to success

Despite its success in deploying 8,342 refrigerators to date, Kenya now faces the challenge of maintaining the CCE. The current staff of 490 cold chain technicians are insufficient in number and face the additional challenges of limited transportation and technical resources that hinder their ability to respond to CCE malfunctions effectively and efficiently. [12]

While considerable progress has been achieved to date through nearly 50 percent equipment optimization and 92 percent functionality rates, continued expansion of the cold chain will inevitably result in increased maintenance needs. Kenya’s cold chain expansion proves that this ecosystem is only as strong as its weakest link. There is a need to strengthen the cold chain holistically, rather than in silos. Integrated planning, increased budgetary allocation aligning equipment scale-up with maintenance resources, and a systems approach must be firmly in place to ensure the sustained national scale-up of this lifesaving equipment.

Notes and references

[1] Kenya National Cold Chain Inventory, 2016 and 2021

[2] https://data.worldbank.org/indicator/EG.ELC.ACCS.ZS?locations=KE

[3] Kenya National Cold Chain Inventory, 2016

[4] Costs are based on reported facility expenditure in 2016 and are inclusive of logistical expenditure (i.e., motorbike fuel).

[5] Ibid.

[6] Kenya Temperature Monitoring Study, 2018

[7] Cold Chain Equipment Optimisation Platform: Technology Guide, Gavi, 2019

[8] Ibid.

[9] Unqualified storage refrigerators refer to equipment not designed for vaccine cold chain.

[10] Kenya National Cold Chain Inventory, 2021

[11] Ibid.

[12] Ibid.

Country

KenyaGoal 7 target

SDG 7.3 - Energy efficiencyInnovation in clean cooking: solving the challenge of fuel distribution

Editor's pick: From jobs to gender equality – why it’s vital we back energy access skills

Technicians are trained in five solar academies across the country, established by the KYA-Energy Group. The company’s CEO Ketowoglo Yao Azoumah predicts that solar skills could soon become a handy export business for Togo – with technicians and local companies finding employment in neighbouring countries across West Africa.

As women face barriers to entering science, engineering and technology sectors, the agency ensured that half of the engineers delivering the work are women.

When it comes to green skills, government action essential – but politicians must work in partnership with forward thinking enterprises and NGOs, that ensure training specifically tackles social inequality. Here are again, there are shining lights to show us the way forward, bringing energy access and workplace opportunities for women.

Kenya’s Burn Manufacturing produces affordable cookstoves that slash carbon emissions and protect the health of families that use them. 60 percent of their employees are female, and have often broken social barriers to train in jobs normally the preserve of men. This dynamic workforce has pushed the company to become a market leader – just a few weeks ago, Burn sold their millionth stove.

Training for green jobs can also spread powerful digital skills. Frontier Markets’ Solar Sahelis are rural women entrepreneurs selling clean energy goods and other products in their communities. An e-commerce app is now central to the organisation’s business model, bringing the sahelis new tech skills to complement their formidable community knowledge and sales abilities.

Huge barriers remain

While these success stories are worth celebrating, they are the exception rather than the rule. In recent years the International Renewable Energy Agency has identified a global need for better public-private partnerships, and action to remedy huge inequalities in access to training and employment among low-income communities and other marginalised groups, especially women. The organisation also calls for national green skills policies, efforts to map training needs, and new channels to connect employers with potential employees.

These concerns have spurred the launch of the 2021 Ashden Award for Energy Access Skills. We are on the hunt for outstanding examples of inclusive and barrier-breaking skills development. The winner will receive a £20,000 grant, while all finalists are given marketing and business support, and access to Ashden’s network of funders, investors and expert partners. Ashden will also fund a powerful promotional film about the winner’s work. Entry is free, and applications close on 17 March 2021.

This week jobs and training are on the agenda at the timely Sustainable Energy for All Youth Summit. Green skills are relevant to every age group, but of particular concern for young people, who have done so much for all of us by raising their voices in support of climate action. Now we can support them by ensuring energy access skills are available to all, and delivered as powerfully as possible.

Discover more about the 2021 Ashden Awards

Follow the Youth Summit at #YouthLeadSDG7

Goal 7 target

SDG 7.1 - Access to energyPartner

AshdenAcacia Innovations provides clean cooking for schools in Kenya

Highlights

When it’s lunchtime in Kenya’s schools, a heavy smoke fills the air. Mostly wood fuel and charcoal are used to prepare student meals. This practice comes with high costs for the environment, the health of cooks and students, and it is a financial burden for parents and schools. Using charcoal as a primary local source of fuel has largely contributed to Kenya’s massive deforestation. Once rich forests are now areas of dry land.

A large portion of fuel demand comes from Kenya’s schools. About 90 percent of public schools use firewood for cooking and pay up to USD 20,000 per year for the wood, which makes cooking fuel one of the biggest expenses in schools’ meal budgets.

Launched in October 2016, Acacia Innovations manufactures and distributes non-carbonized briquettes made of sugarcane waste, called Kuni Safi (which means “clean firewood” in Swahili). It distributes these eco-friendly briquettes mainly to schools and small businesses such as bakeries, a market that is often overlooked by other clean fuel providers targeting either large-scale industry or households.

The founder and CEO of Acacia Innovations, Elana Laichena, is an entrepreneur with experience in the renewable energy and clean cooking sector in Kenya and the US. "So far, we are the largest supplier of clean cooking fuels to schools in Kenya, with over 350 school customers in 20 counties," Laichena said. "We have sold over 4,000 tons of Kuni Safi briquettes to date, saving 100,000 trees and impacting over 175,000 school children by providing a smoke-free learning environment and contributing to affordable school meals. We have also created jobs for over 100 Kenyans, and over 50 percent are women."

Laichena noticed that no one was effectively serving schools and small businesses, which are major consumers of firewood in Kenya. "We estimate these institutions consume over 685,000 tons of firewood and charcoal per year. I decided to start a company focused on providing a cost-saving and eco-friendly cooking solution for schools since there is also a big social benefit of contributing to affordable meals for school children. We started as a distributor in October 2016, and when our demand exceeded supply, we set up our own factory in May 2018."

Kuni Safi briquettes are made of sugarcane fiber, which is abundant in Kenya. For every ton of briquettes, about four cubic meters of agricultural waste is recycled and 25 trees are conserved. These trees left standing will save five tons of CO2 over their lifetime. The briquettes burn nearly smoke-free and almost eliminate the smoke in school kitchens. Cooks no longer suffer from coughs and watery eyes and have a lower risk of pneumonia, lung cancer, heart disease and chronic obstructive pulmonary disease.

Although the briquettes can be used with any stove or hot water heater, Acacia Innovations also developed an energy-saving cookstove, especially for schools. The stoves that are manufactured locally are the first portable, institutional cookstoves in Kenya that can be used with non-carbonized briquettes, but also with firewood or charcoal

The company has already won several prizes for its innovative technology, such as the 2018 Start-Up Energy Transition Award and the Women in Energy Kenya Award. With the Energy Access Booster Award, Acacia Innovations will be able to reach even more schools and small businesses. "We are excited to work with the consultants in the Energy Access Booster team to be able to assess our pricing and see if we can better optimize our revenues while still delivering cost savings to our customers", Laichena said. "The money will be important for our company to expand our factory infrastructure and mitigate the economic downturn due to coronavirus."

Country

KenyaProgramme

Clean CookingEnergy Safety Nets: Kenya Case Study

Video: Philips Community Life Centers

Community Life Centers can offer a wide range of clinical and medical device training to help improve competencies. Combined with service offerings for maintenance and repair, the centers help ensure an improvement in quality, readiness and responsiveness of the facility, which is so often lacking.

Philips launched Africa's first Community Life Center in GithuraiLang'ata, Kenya aimed at strengthening primary health care and enabling community health development. Other centers have been set up in South Africa, Namibia and DR Congo, with plans to deploy these centers across the African continent.

Find out more about the 2019 Seven for 7 honorees.