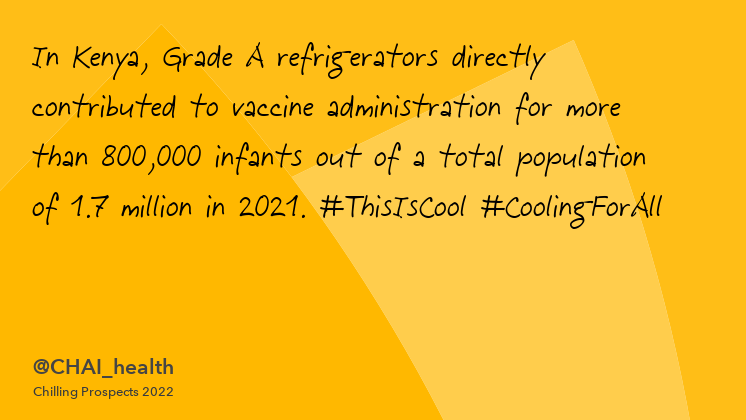

Chilling Prospects 2022: Expanding the vaccine cold chain in Kenya through innovative cooling solutions

|

Reflections on five years of the Kigali Amendment by the Clinton Health Access Initiative |

The lack of reliable electricity at public health facilities in Kenya has been a significant challenge to expanding its vaccine cold chain. While residential energy access increased from 52 percent to 70 percent between 2016 and 2019, energy access at government-operated health facilities only grew by 1 percent from 69 percent to 70 percent in the five-year period 2016 to 2021. [1] [2]

Historically, and in the absence of reliable electricity, absorption technology refrigerators have played a key role in expanding the cold chain. This cooling technology is intended to be mains powered with liquified petroleum gas (LPG) serving as a backup. However, in 2016, 13 percent of facilities relied entirely on LPG as a main source of power as they lacked access to any other form of electricity. [3] Despite effectively expanding the cold chain where it otherwise did not exist, LPG refrigerators proved to be environmentally damaging, expensive and unreliable. [4]

With an estimated monthly LPG consumption rate of 11.4 kg, these refrigerators consume approximately 123 tonnes of LPG in a single year and cost USD 422 per health facility. [5] They also have shorter life spans than optimal cold chain equipment (CCE) and are often responsible for vaccines freezing as they lack freeze-protection mechanisms. This contributes to a facility-based freeze excursion rate of 3.5 percent. [6]

Optimizing the cold chain with innovative cooling solutions

To overcome the challenge of a costly and environmentally damaging cold chain, the Ministry of Health (MoH) has set the ambitious goal of strengthening the vaccine supply chain by equipping all facilities with optimal CCE by 2026. Optimal CCE consists of cooling solutions that meet a standard of performance criteria set out in the World Health Organization’s (WHO) Performance, Quality, and Safety Catalogue requirements that is referred to as platform-eligible CCE (in line with Gavi’s Cold Chain Equipment Optimization Platform (CCEOP)). [7]

Key performance features include Grade A user-independent freeze protection, meaning that without any human action these appliances ensure vaccines are not exposed to damaging freezing temperatures. They also possess greater holdover time, i.e., the number of hours that an appliance remains below 10°C during power outages. Finally, these innovative cooling solutions can operate at higher ambient temperatures and are equipped with voltage protection that will maintain functionality in volatile power conditions. [8] Importantly, they do not use any fossil fuels for power, resulting in a climate-friendly cold chain that is often more cost-effective over its lifespan.